AVAILABLE TECHNICAL EQUIPMENT

Turning:

CNC lathes:

max. diameter

280 mm

max. length

400 mm

accuracy

0,005 mm

roughness

Ra 0,4

NC lathes:

max. diameter

160 mm

max. length

250 mm

accuracy

0,01 mm

roughness

Ra 0,8

Universal lathes:

max. diameter

800 mm

max. length

200 mm

accuracy

0,05 mm

roughness

Ra 1,6

max. diameter

250 mm

max. length

1 800 mm

accuracy

0,05 mm

roughness

Ra 1,6

Milling:

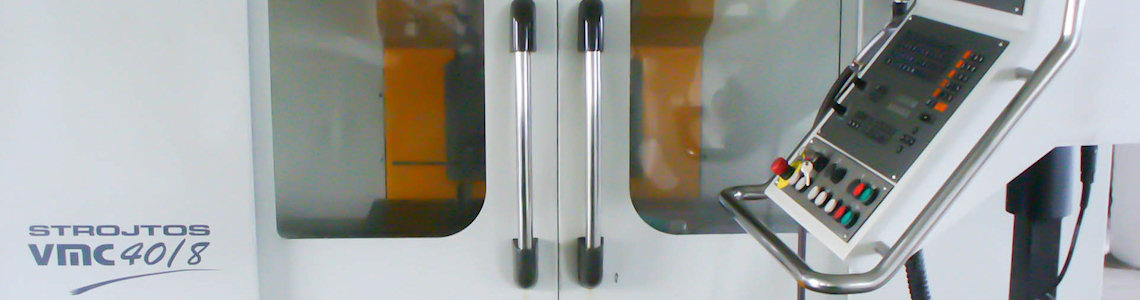

CNC milling centre:

max. dimensions

1 250 x 560 x 560 mm

accuracy

0,005 mm

roughness

Ra 0,8

Universal milling machines:

max. length

1 200 mm

max. width

450 mm

max. height

400 mm

accuracy

0,02 mm

roughness

Ra 1,6

Horizontal milling machines:

max. length

1 200 mm

max. width

800 mm

max. height

450 mm

accuracy

0,02 mm

roughness

Ra 1,6

Cutting:

Band saw

max. diameter

300 mm

Grinding:

Surface grinding machines:

max. length

500 mm

max. width

250 mm

accuracy

0,002 mm

roughness

Ra 0,2

Cylindrical grinding machines:

– grinding of external cylindrical holes

max. diameter

200 mm

max. length

800 mm

accuracy

0,002 mm

roughness

Ra 0,2

– grinding of internal cylindrical holes

max. diameter

150 mm

max. length

150 mm

accuracy

0,002 mm

roughness

Ra 0,2

Profile grinders:

– grinding various shapes according to customer’s requirements

Drilling holes:

Vertical drilling machine

range of work positions

1 200 x 1 200 x 1 100 mm

positioning accuracy

5/1000

Manufacture of grooves:

groove width

2 ➗ 16 mm

groove depth

up to 150 mm

roughness

Ra 0,8

Welding:

MIG welding – common structural steel grades

TIG welding – structural and stainless steel grades

Sheet-metal processing:

We process the sheet rolls up to 300mm wide and 4mm thick

The production lines have uncoiling, straightening and feeding devices

We keep eccentric press with capacity of 10 to 100 tons at disposal